Bosch Invests €2.9B in AI for Manufacturing & Supply Chain

Generally, Companies like Bosch are investing heavily in artificial intelligence, Normally, this is to improve efficiency and adaptability in manufacturing and supply chain management. Obviously, Bosch is planning to invest €2.9 billion in AI by 2027, Mainly, to enhance operational efficiency and adaptability in real-world conditions.

Normally, You will see significant investments in AI aimed at improving manufacturing processes and supply chain management. Usually, AI is used to detect quality issues earlier in the production process, By analyzing data from cameras and sensors, AI models can identify minor variations in materials or machine settings that could lead to defects.

Bosch Invests €2.9 Billion in AI for Manufacturing and Supply Chain

Apparently, Bosch is utilizing AI to improve operational efficiency, Sometimes, this is done by analyzing data from various sources, Including cameras and sensors. Typically, AI models can identify minor variations in materials or machine settings that could lead to defects, Normally, this allows workers to address issues before they escalate.

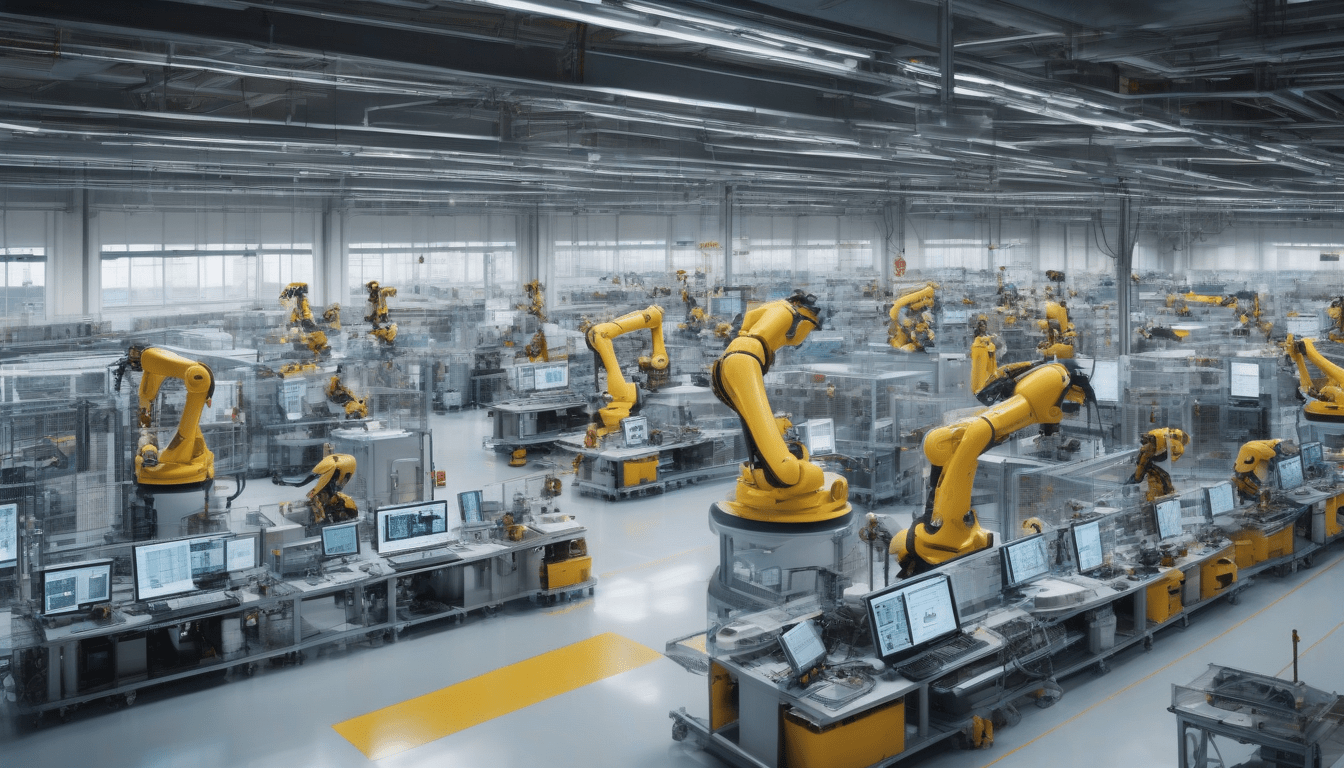

AI in Manufacturing

Actually, In manufacturing, AI is being used to detect quality issues, Often, by analyzing data from cameras and sensors, AI models can identify minor variations in materials or machine settings that could lead to defects. Usually, This early detection allows workers to address issues before they escalate, Reducing waste and the need for rework.

Generally, You can see how AI is being applied in manufacturing to improve efficiency, Sometimes, this is done by predicting equipment maintenance needs, By training models on data such as vibration, temperature, and usage patterns.

Predictive Maintenance

Obviously, AI is also being applied to predict equipment maintenance needs, Normally, by training models on data such as vibration, temperature, and usage patterns, Bosch can forecast when machines are likely to fail. Usually, This predictive maintenance approach helps to minimize unplanned downtime and extend the lifespan of equipment, Ensuring more stable production.

Apparently, You will see that predictive maintenance is crucial for managing equipment, Sometimes, this is done by using AI to forecast when machines are likely to fail.

Supply Chain Management

Normally, Supply chain management is another key area of focus, Generally, AI systems are being used to forecast demand, track parts across multiple sites, and adjust plans in response to changing conditions. Usually, This adaptability is crucial for managing the ongoing challenges of shifting demand and transport delays.

Actually, You can see how AI is being applied in supply chain management to improve efficiency, Sometimes, this is done by using AI to forecast demand and track parts across multiple sites.

Perception Systems

Generally, Bosch is also investing in perception systems, Obviously, which enable machines to understand their surroundings, Sometimes, these systems combine input from cameras, radar, and other sensors with AI models that can recognize objects, judge distances, and spot environmental changes. Usually, This technology is particularly useful in factory automation, driver assistance, and robotics, where real-time responses are essential.

Edge Computing

Apparently, Edge computing plays a vital role in these operations, Normally, by processing data locally on factory floors and in vehicles, AI models can respond in real time without relying on distant cloud systems. Usually, This approach reduces delays and ensures continuous operation even when network connections are unreliable, Additionally, it helps keep sensitive data on-site, which is important for industrial companies with closely guarded production processes.

Actually, You will see that edge computing is crucial for real-time responses, Sometimes, this is done by processing data locally on factory floors and in vehicles.

Industry Impact

Obviously, The scale of Bosch’s investment is notable, Generally, as many companies are still in the pilot stage with AI, Normally, Bosch views AI as a tool to support workers and manage complexity rather than replace human labor. Usually, This perspective reflects a broader industry trend where AI is increasingly seen as essential infrastructure for improving efficiency and reducing waste.

Apparently, You can see how Bosch’s commitment to AI highlights the company’s focus on operational use rather than customer-facing features, Sometimes, by integrating AI into core operations, Bosch aims to enhance manufacturing efficiency, improve supply chain adaptability, and manage complex systems more effectively.