Siemens Unveils Tech to Boost Industrial AI

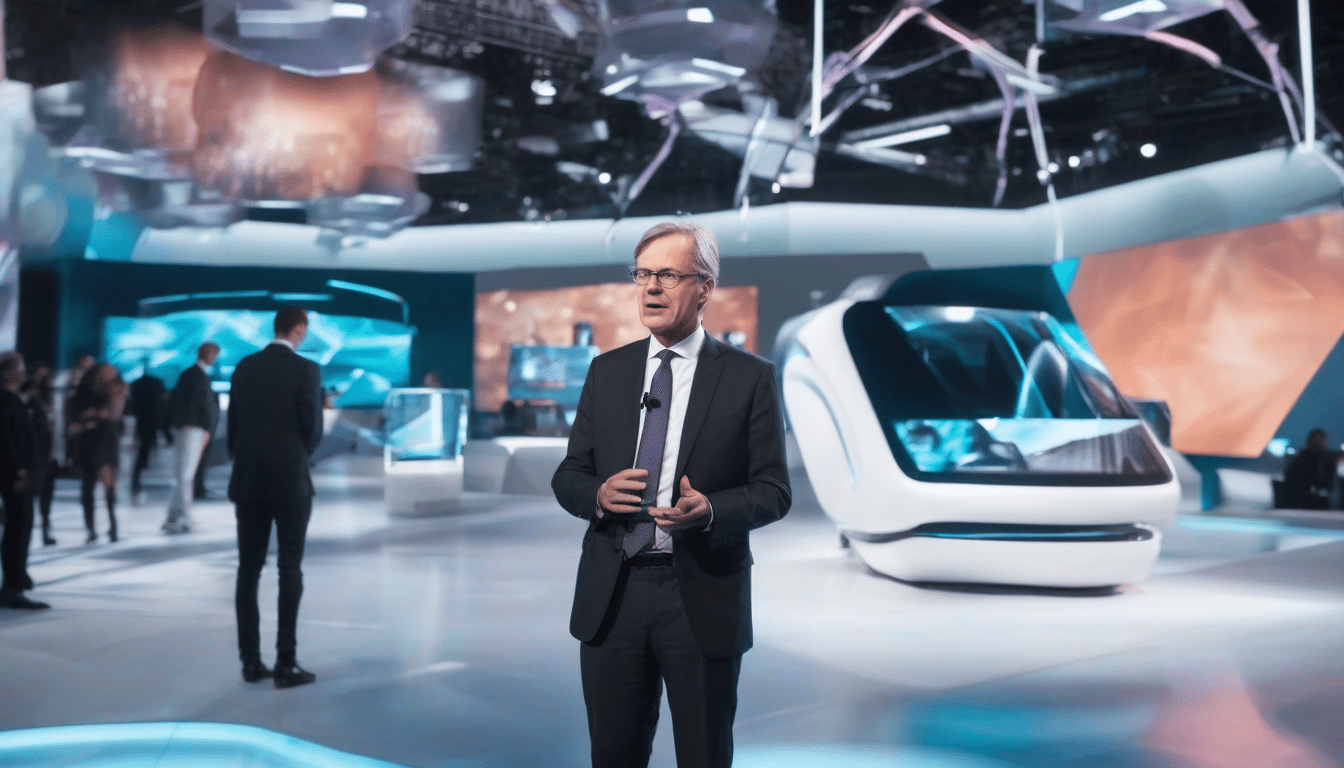

Generally, You Should Know That Siemens has announced a bunch of new AI technologies and partnerships at CES in Las Vegas, which is really cool. Obviously, The company’s CEO, Roland Busch, says that industrial AI is becoming a big deal that will change industries in the next century. Usually, Siemens is trying to put AI-native capabilities into design, engineering, and operations to help businesses predict problems, come up with new ideas, and save money.

Expanded Partnership with Nvidia

Normally, A key part of Siemens’ announcement is their new partnership with Nvidia, which is a big player in AI. Apparently, They plan to work together to create an industrial AI operating system that will help customers make and manage physical AI systems. Sometimes, This partnership will use Nvidia’s AI infrastructure, simulation libraries, models, and frameworks, along with Siemens’ industrial software, hardware, and expertise.

What They Will Focus On

Clearly, The partnership will focus on four main areas, including AI-native electronic design automation, AI-native simulation, AI-driven adaptive manufacturing and supply chains, and AI factories. Usually, The goal is to make the world’s first fully AI-driven, adaptive manufacturing sites, and they will start by implementing it at Siemens’ Electronics Factory in Erlangen, Germany, in 2026. Obviously, This is a big deal for the industry.

Digital Twin Composer Platform

Generally, Siemens also launched the Digital Twin Composer, which is a platform that will power the industrial metaverse at scale. Apparently, By combining Siemens’ digital twin technology with Nvidia Omniverse simulation libraries and real-time engineering data, companies can build and test high-fidelity virtual models of products and processes. Sometimes, This allows for AI-driven simulations before making physical changes, which can save a lot of time and money.

How It Will Work

Normally, The platform will be available on the Siemens Xcelerator Marketplace by mid-2026, and some companies are already using it. Usually, PepsiCo is one of the early adopters, and they have used it to create high-quality recreations of entire plants, simulating operations and identifying potential issues before physical implementation. Obviously, This is a great example of how this technology can be used.

AI-Powered Industrial Copilots

Clearly, Siemens also introduced nine new AI-powered industrial copilots across its software portfolio, including Teamcenter, Polarion, and Opcenter. Apparently, These copilots are designed to streamline product data navigation, automate compliance workflows, and optimize manufacturing operations. Sometimes, They aim to reduce errors, speed up regulatory approvals, and drive cost savings on the shop floor, which is really important for businesses.

Conclusion

Generally, The announcements show that Siemens is committed to integrating AI into industrial processes, fostering innovation, and enhancing operational efficiency. Obviously, This is a big step forward for the industry, and we can expect to see more developments in the future. Usually, You should keep an eye on Siemens and their partners to see what they come up with next.